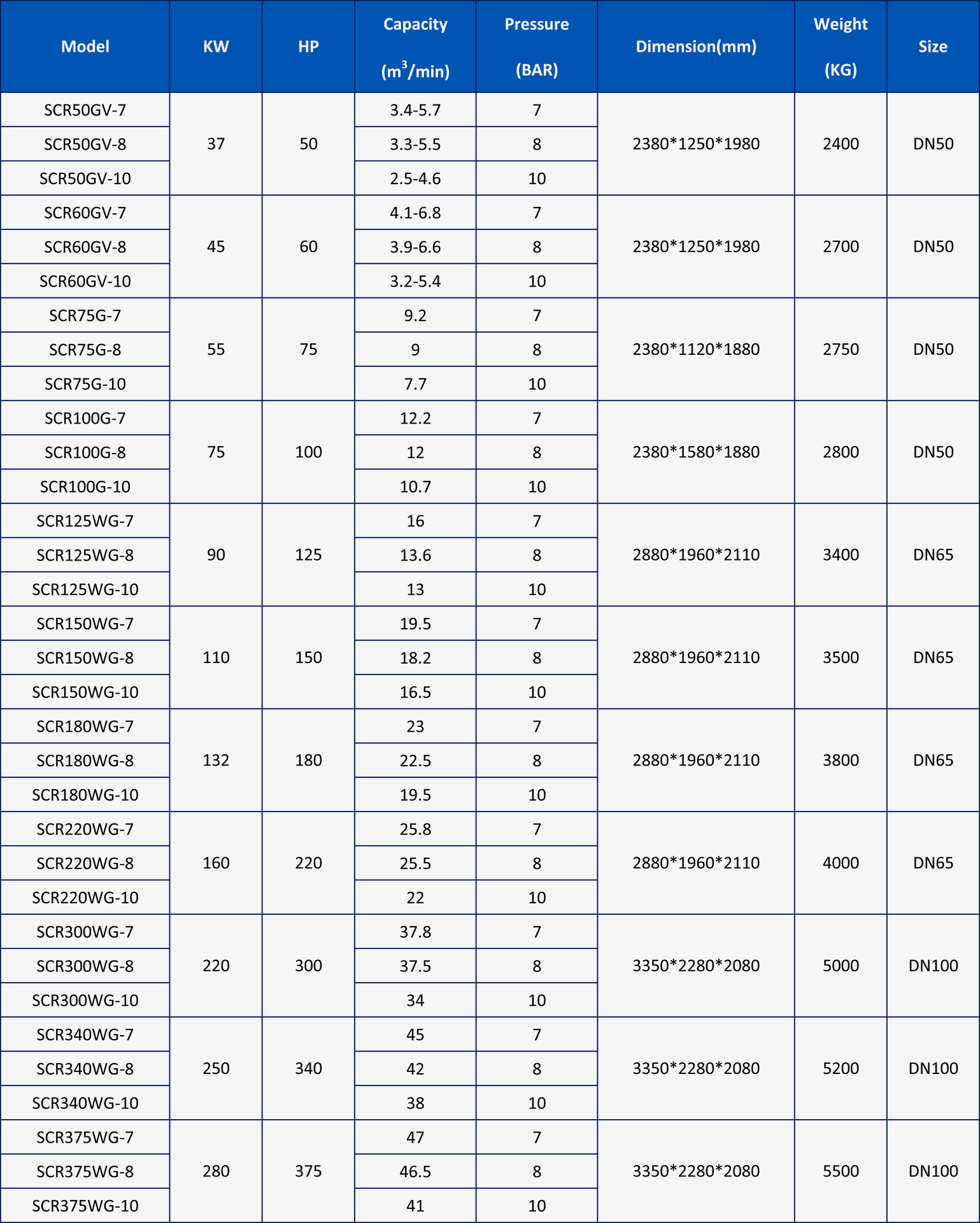

Dry Oil Free Screw Compressor G series

Working Power: 37~280 KW (50~375 HP)

Free Air Delivery: 2.5~47 m³/min (88.3~1660 cfm)

Working Pressure: 7/8/10 bar (101.5/116/145 psig)

PRODUCT ADVANTAGES

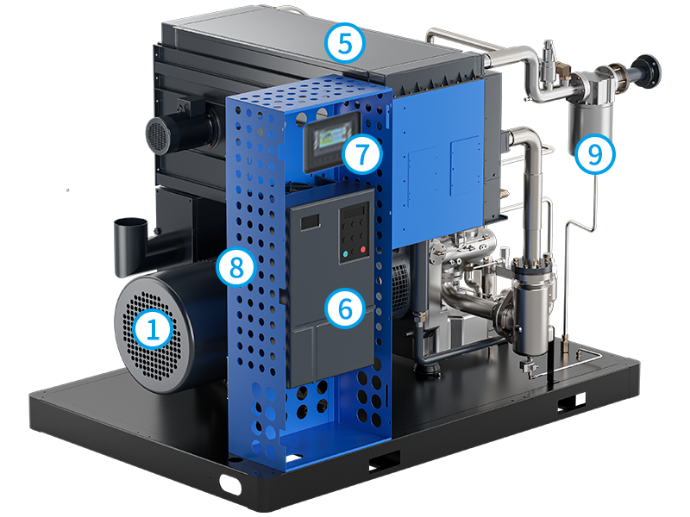

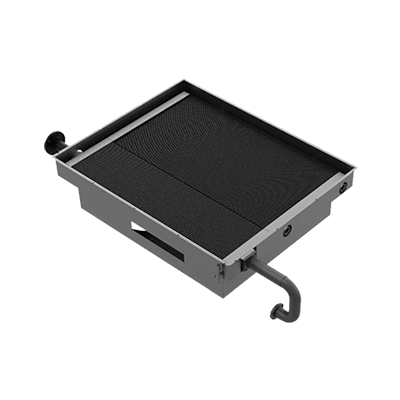

PRODUCT PARTS

PRODUCT DETAILS

① Motor

● Standard TEFC motor specially designed for heavy-duty application.

● IP54 (IP55 option) protection grade ensure the stable running even at dusty environment.

● Reliable and proved on the market for more than 15 years.

② Oil Free Air end

● Germany GHH rand oil free air end, proved on the market more than 50 years.

● Two stage dry compression guarantees 100% oil free air.

● Stainless steel rotor for the second stage compressor ensure no rust even after long-term running.

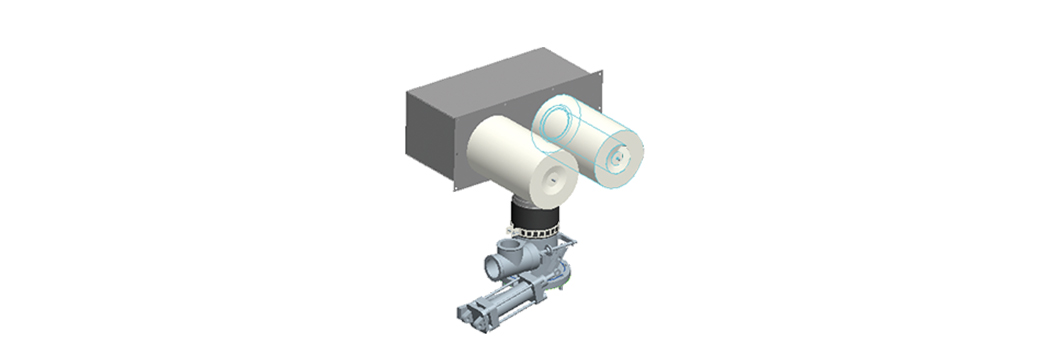

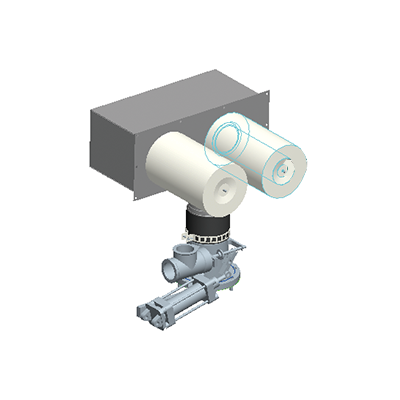

③ Inlet filter

● Independent inlet sound box ensures equal air filter inlet and the environment temperature.

● Inlet sound box reduces the noise level of compressor.

● High precision air filter ensures good filtration and improves the stable operation of compressor.

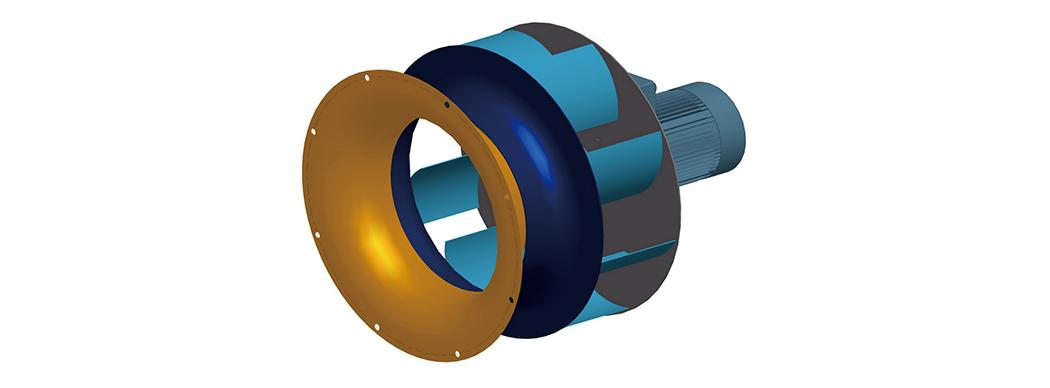

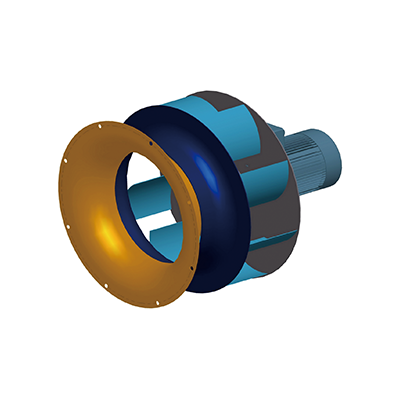

④ Centrifugal fans

● New centrifugal fan guarantees proper cooling.

●Uniform air pressure and heat dissipation means better cooling.

⑤ Classic cooler design

● High resistant cooler of 280 deg C

●Anti-corrosion paint.

⑥ Innovative vectorial inverter

● CE, UL, CUL, ROHS certification

● Meet EMC C3 and C2 requirements

● Independent cooling air duct design

●

VSD control is standard for 50HP/60HP, above 60HP are optional.

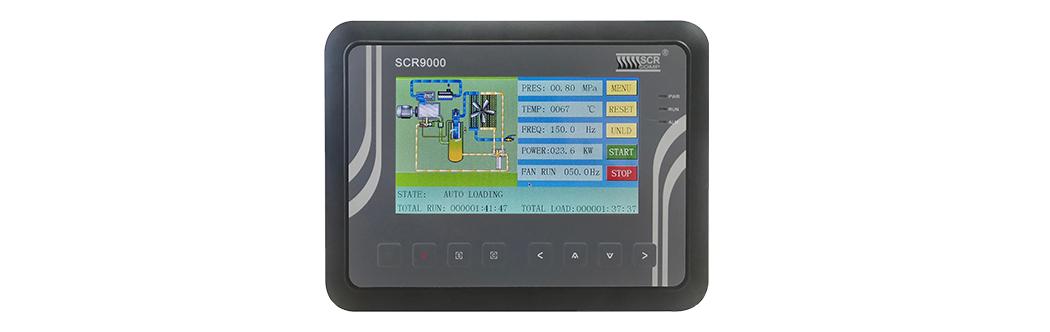

⑦ SCR9000 Touch Screen PLC

● 7.0 inch full color LCD touch screen

● Real-time Operation/ Maintenance/ Alarm information

● Operation record/ Chart display

●Weekly timer/Service history and planning

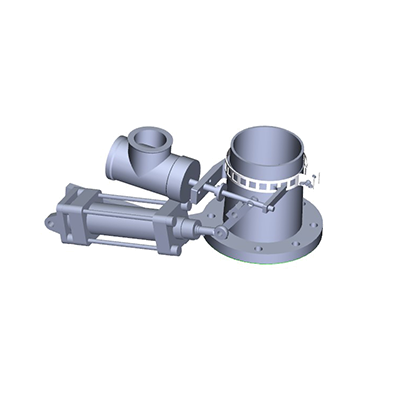

⑧ Inlet valve

● Optimized inlet air flow.

● No blow-off losses / Large suction area

●Full aluminum design: maintenance-free.

⑨ Water separator

● Efficiently removes water from compressed air, guarantees the dehumidification of compressed air.