صرف نظر و مشاهده محتوا

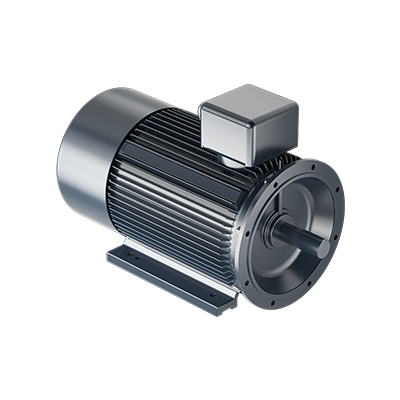

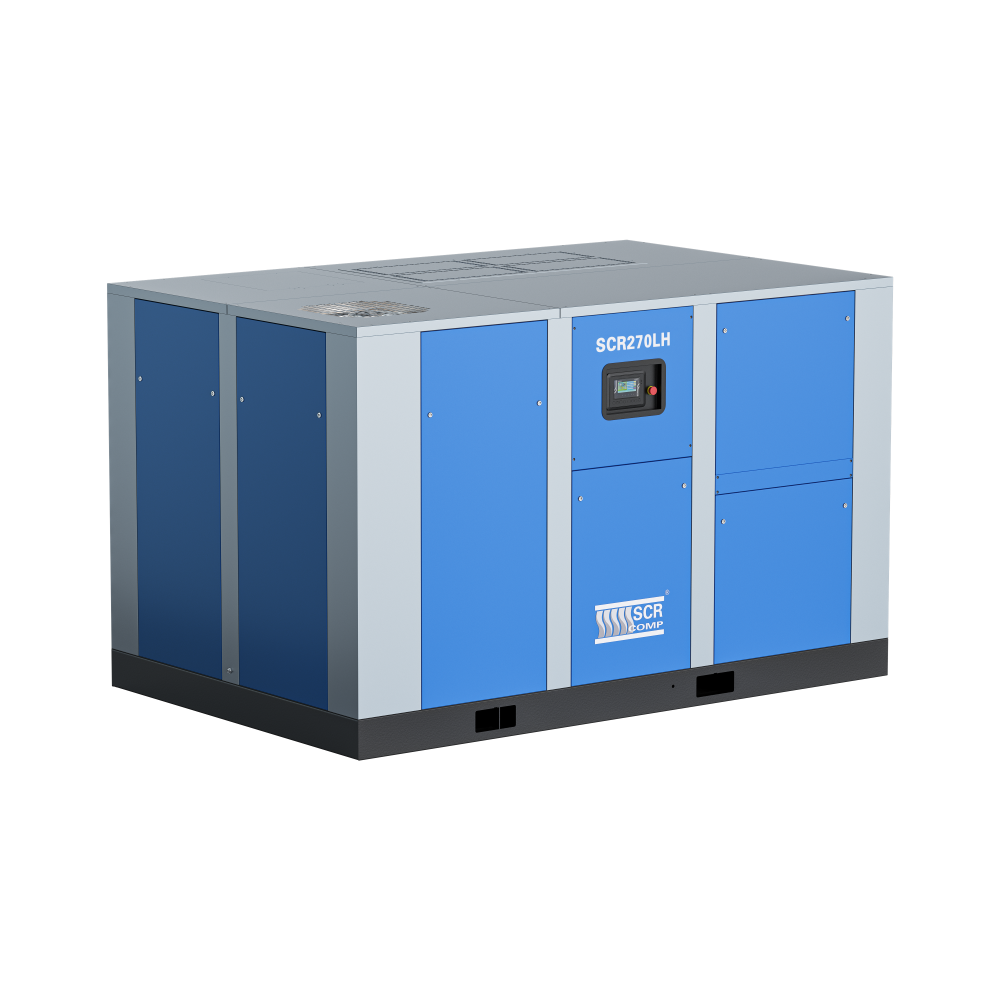

Low Pressure Two Stage Screw Compressor LH/LHPM Series

Working Power: 55~250KW(75~335HP)

Free Air Delivery: 4.5~62m³/min(159~2190.5cfm)

Working Pressure: 4.5/5.5bar(65/79 psig)

1 Low power, high energy saving

Almost 10% less power consumption

compared to equal size single stage screw compressor.

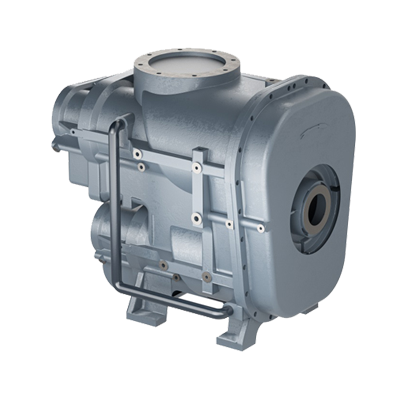

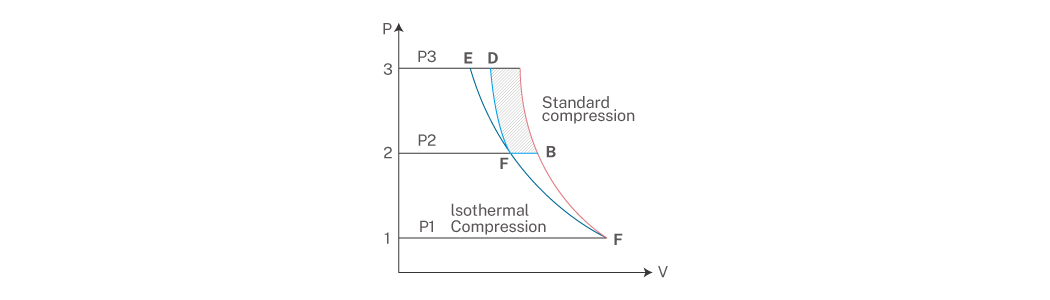

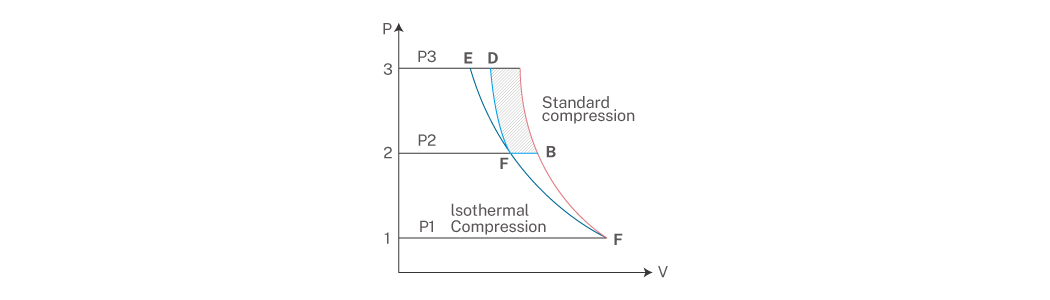

2 Near isothermal compression

AFE31 represents isothermal compression

AC31 is area of standard compression

AB,BF,FD,31 is area of two stage compression

Two stage compression saving area is BCDF comparison with standard compression

★After first grade compression, the volume of compressed air become smaller, then the second compression could use smaller rotor, which reduce the compression leakage.

It reduces the compression ratio and the leakage.

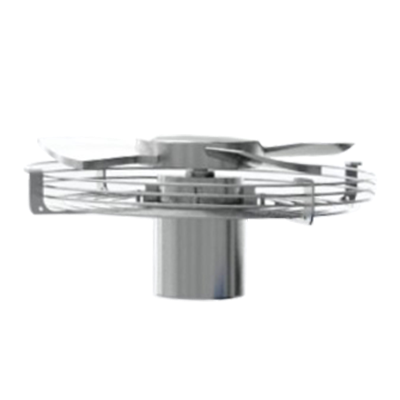

3

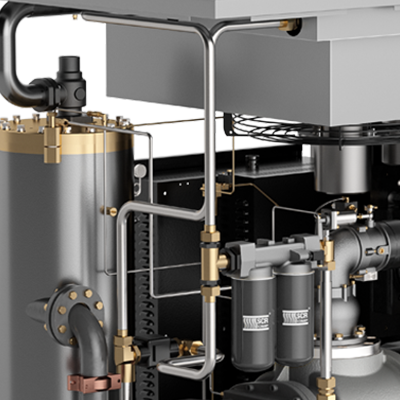

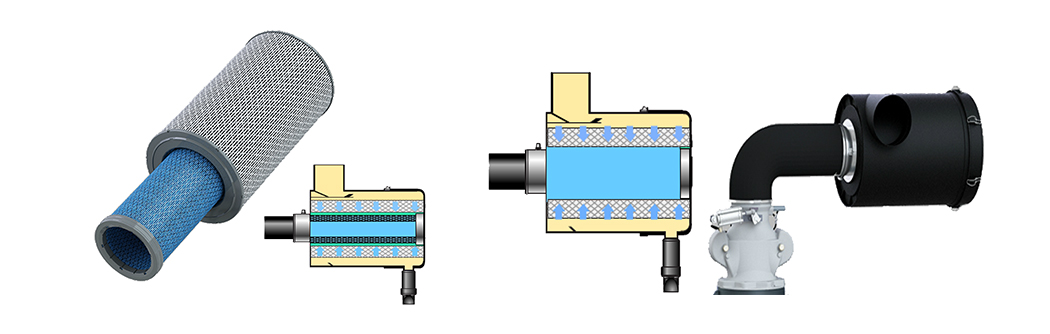

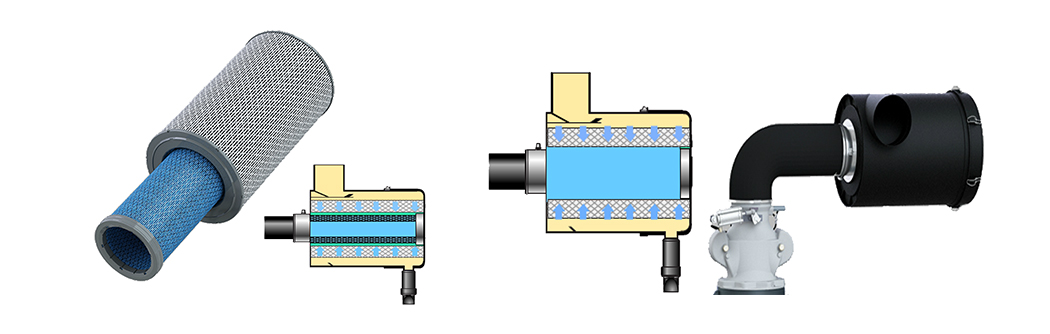

Heavy Duty Air Filter:

Double

filter core, improved filtration, long service life, low suction

resistance, improved air inlet efficiency.

Made

for dusty environment like: cement, textile, fiber, chemical industry, etc.

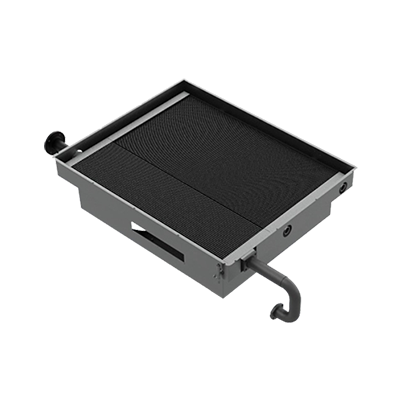

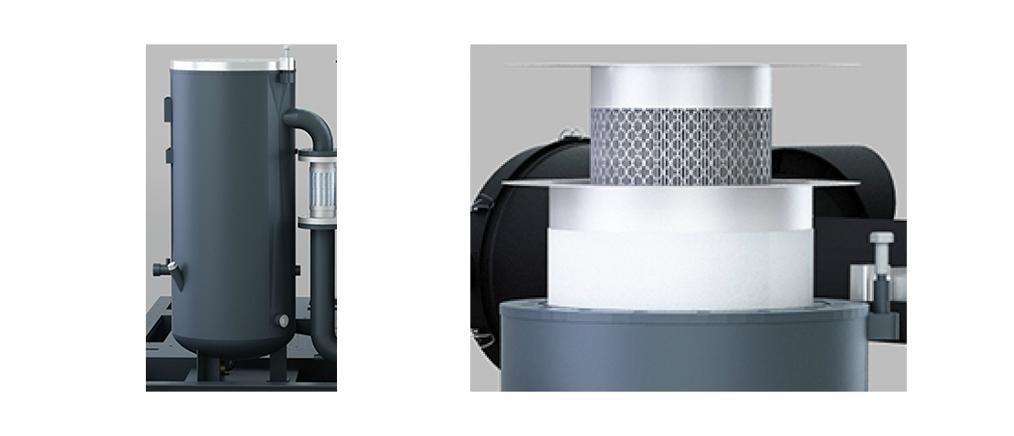

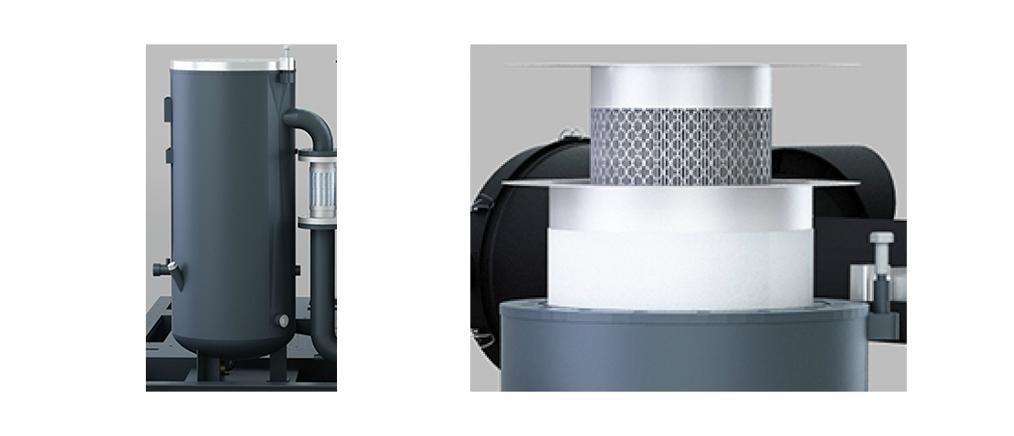

Oil/air tank(125HP-300HP)

Large capacity oil tank, reduced lubricating

oil foaming.

Tank cover fitted with rotating

aid to ease air/oil separator

Large separator, better

separation, lower pressure drop, improved efficiency.

Double oil separator core for 340HP and

above, better oil separation.

Oil carry-over less than 3PPM over

4000 run hours

PRODUCT PARAMETER

Note:

Data conforms to ISO 1217 (Pressure 1 bar (a), Temperature 20 deg C, R.H 0%)

Standard voltage is 380V/50HZ/3P, other voltage is available.

Alpine/high altitude, high temperature, high humidity, high dust loads or other adverse working conditions will require specialized custom designs. These are available on special request.

We reserve the right to make changes and improvements to the design and appearance.

Specifications may change without prior notice.