An important and interesting subject both the compressor manufacturers and the end users need to know about.

Importance of compressor efficiency stems from its effect on the running cost which accounts for almost 80% of the compressor total life cycle cost.

Efficiency is a general term not limited to a specific field as for example: compressors, engines, pumps, etc. Efficiency applies to any system, industry and even our everyday life. If you find an easy and a less tiring way to do what you did repeatedly in the past, then you are doing it more efficiently and your efficiency has improved!

I have seen different

definitions for the efficiency as for example:

The potential or the objective of reaching a

goal with the lowest waste of power.

Reaching such a goal

obviously calls for the right path and the right tool to use.

If I were to define efficiency in my words, I would say “efficiency is the percentage of an effort made to achieve a goal”. Goal, also called the “output” is less than the effort or “input” because the effort always includes waste, friction and spoilage, whereas goal is the net achievement.

With this prime definition of the efficiency, let us see what it means in air compressors in general, and rotary screw type, the most widely used model in particular.

I assume those reading this article are familiar with screw compressors principle and operation, with no need for me to start with the basic definitions.

Screw compressors unlike reciprocating models are made for continuous 24/7 operation, delivering their highest efficiency at full load operation.

Focusing on screw compressors, I will use “compression” rather than “process” throughout this article.

Compression in screw compressors is normally of four different efficiencies as:

1. Isentropic

2. Isothermal

3. Volumetric

4. Mechanical

Isentropic Efficiency

The most widely used terminology in compressed air, has its root in isentropic compression assumed to be adiabatic (no heat transfer) and reversible (no waste, loss, spoilage, etc.) throughout the compression.

Isentropic compression only exists theoretically and never in practice because; neither a perfect insulation, nor a zero-loss compression is possible.

What is said above could

raise a big and even a confusing question as:

If in fact isentropic compression is not possible in practice,

why we define it and what its significance is?

Isentropic efficiency is simply a measure of comparison between an ideal and a real compression. It actually shows how a real compression could distance itself from an ideal one.

With the above said, isentropic efficiency is the power ratio of an isentropic compression to a real/ actual compression for a given inlet and outlet points and pressure ratio.

With what we discussed so far we should be in a position to say, that:

- Adiabatic compression, need not necessarily be isentropic

- Isentropic compression must be both adiabatic and reversible

- Isentropic compression which is not adiabatic is not possible

- Isentropic compression must be reversible

- Reversible compression is of no friction and waste power/energy

To better distinguish between an isentropic and an actual compression, I would say “while isentropic compression depends on the inlet and outlet conditions as well as pressure ratio, actual compression takes losses in the bearings and shaft seals, leaks, pressure drop and friction between the moving parts, etc., into account”. It is for this reason that actual power / work is higher than that of isentropic.

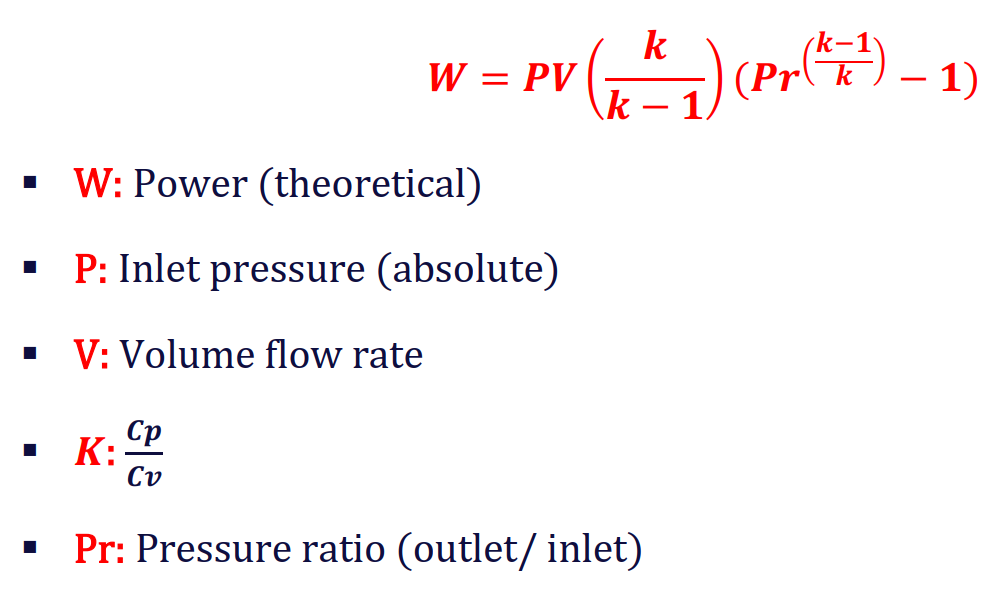

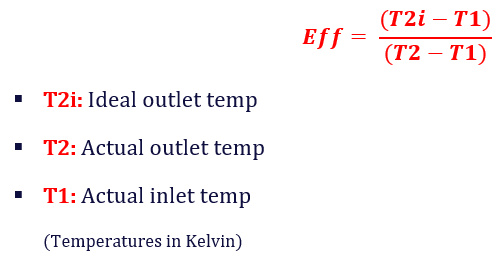

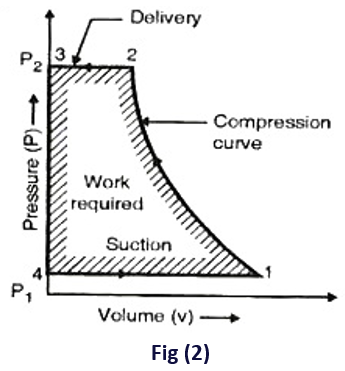

To calculate the isentropic efficiency, we need to work out the isentropic power first.

Isentropic efficiency is the ratio of “W” calculated as above formula to the actual input power.

Alternative formula

which also works for isentropic efficiency is as follows:

With T2 being higher than T2i, isentropic efficiency always remains <100%.

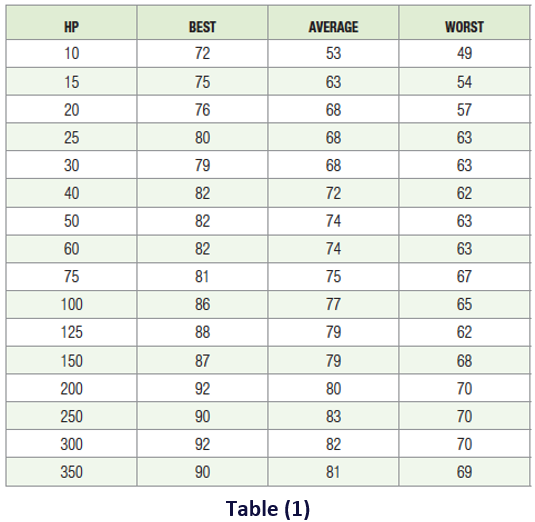

For a well- designed

screw compressor, isentropic efficiency is expected somewhere between 75

to 85%. Large size

compressors are of higher isentropic efficiency compared to small sizes. Table

(1) below shows a comparison of isentropic efficiency for different oil

injected fixed speed screw compressors based on CAGI data sheet.

While the lowest efficiency expected is around 50%, the highest could reach as high as 92%.

As said before, isentropic efficiencies do not refer to the actual output to the input power, but the isentropic output to the actual input power, and are as good as comparison among different compressors rather than an individual compressor.

Isothermal Compression

With this primary information on isentropic compression and efficiency, let us take isothermal compression to discuss.

In isothermal compression, unlike isentropic, temperature remains constant as the compression heat is continuously collected and removed.

Isothermal compression though theoretically of lower power consumption compared to isentropic, is however impractical with the current compressors technology. While in practice actual compression occurs fast, isothermal compression needs to be slow enough to enable to collect the compression heat and dissipate as it generates.

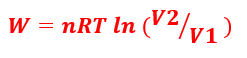

For

isothermal efficiency we need to first calculate the isothermal power or work

required as per formula:

Isothermal efficiency is the ratio of the theoretical power to the actual power.

For a given compression with identical start points and pressure ratio, isothermal power or work is lower than isentropic, and therefore is of higher efficiency.

With this brief introduction to both isentropic and isothermal compression, let us review another compression, the so called polytropic, you might have heard about.

Polytropic Compression

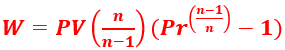

Polytropic compression is neither as insulated as isentropic with no heat transfer and friction, nor of a fixed compression temperature as in isothermal, but moderately a combination of the two.

Formula

applies with “n” being the so called polytropic

exponent.

applies with “n” being the so called polytropic

exponent.

Polytropic power and

efficiency lie between the isentropic and isothermal. Fig (1)

Volumetric Efficiency

As the name implies, this is the ratio of the volume of air delivered -corrected to the inlet conditions- to the intake air. Volumetric efficiency more applies to reciprocating compressors with their delivery being 60-65% of their intake air. Screw compressors, being of no clearance volume are of higher volumetric efficiency. A little difference between the delivery and the intake could be due to the internal leakage and/or air back flow, etc.

Mechanical Efficiency

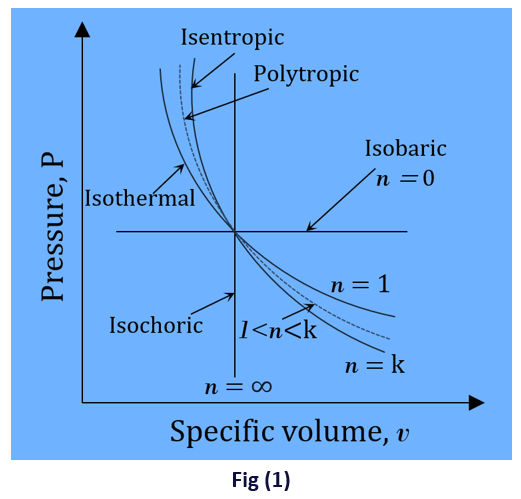

Mechanical efficiency is the ratio of the compression power calculated from the PV indicator diagram, to the electric motor shaft power or the break horse power (BHP). See Fig (2).

As shown in the figure,

while compression is expected polytropic, air is pushed out at constant

pressure – more importantly with no clearance volume- followed by air pressure

reduction and fresh air intake. When drawn to correct scale, the area shown in the

diagram represents the work done. And could be measured using the apparatus

called planimeter.

Efficiencies explained above mainly apply to the air ends, but this is not the whole story as improving compressor efficiency calls for more steps to take as follows:

- Humid inlet air could be of adverse effect building moisture in the compressor.

- Dirty and contaminated air could cause wear and tear within the air end, intake vale, elsewhere.

- High inlet air temperature causes more power to consume.

- Heat recovery is of a great help as a big portion of compression power turns into heat.

- Reservoir helps reduce unloaded power consumption of compressors.

- Correct location of compressor with an access to cold air helps reduce running cost.

- Correct size compressor for the demand, helps reduce unloaded running cost.

- Leaks account for big losses.

- Routine and preemptive maintenance is a must.

- Correct size piping is vital.

- Shorter pipe length from the compressor to the end users is highly important.

- Downstream equipment removes humidity and improve production.

EFFICIENCY IN AIR COMPRESSORS