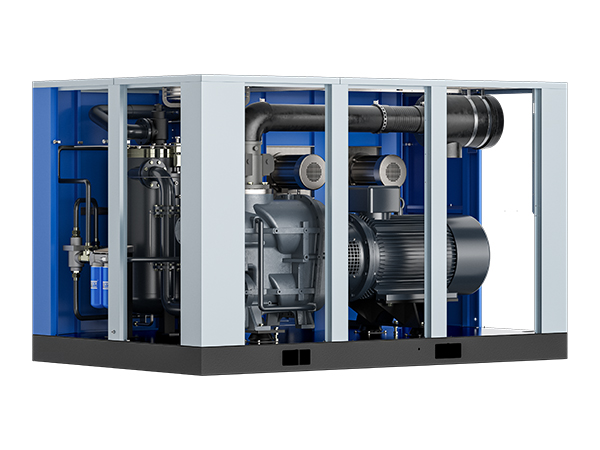

Two Stage H Series Screw Compressors

Working Power: 132~315 KW (180~400 HP)

Free Air Delivery: 18.5~63.2 m³/min (653~2231 cfm)

Working Pressure: 7/8/10/12.5 bar (101.5/116/145/181 psig)

PRODUCT ADVANTAGES

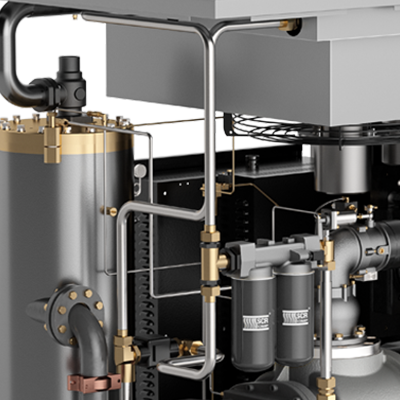

PRODUCT PARTS

PRODUCT DETAILS

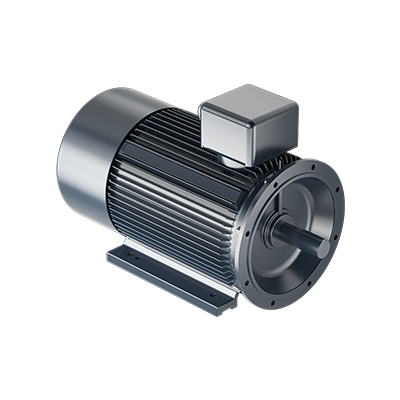

① Premium Efficiency Drive Motor

● Premium efficiency Totally Enclosed Fan Cooled (TEFC) IP54/IP55 Class (F)

● Long-term stable operation under harsh environments

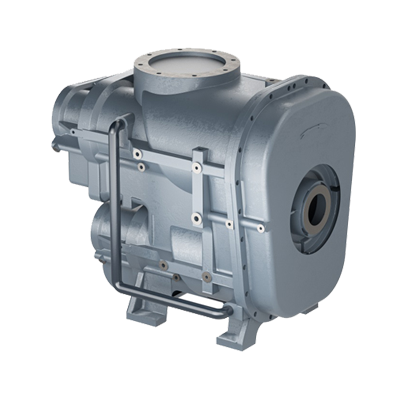

② Innovative air end

● New improved rotor profile for low pressure application

● High quality class bearings

● Designed for 20 years of reliable operation

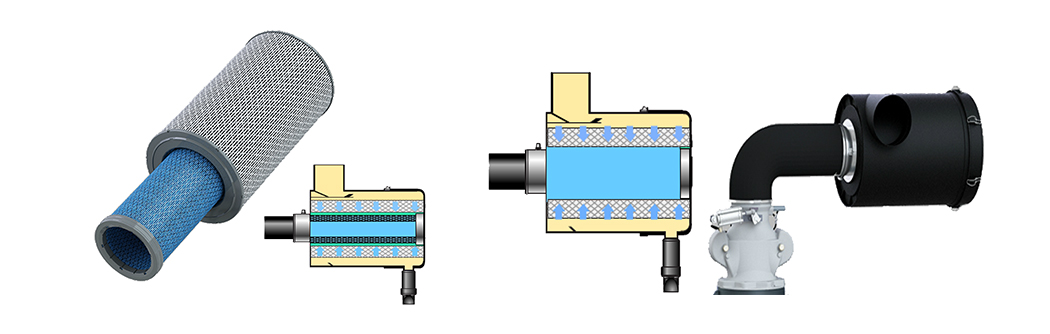

③ Inlet filter

● Nano scale Heavy duty

● Filtration efficiency up to 99.9%

● Dust particles < 0.3 micron

● Differential pressure indicator

● 2,000 hours service intervals

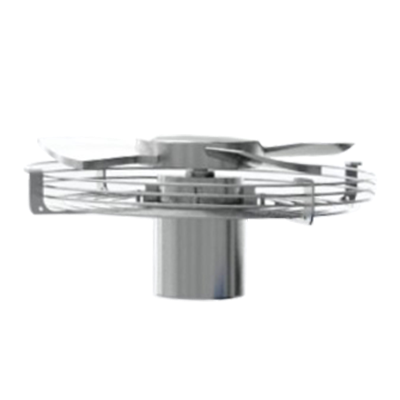

④ Cooling fan

● VSD control

● Compact

● Low noise level

● High capacity for optimized cooling

● Low power consumption

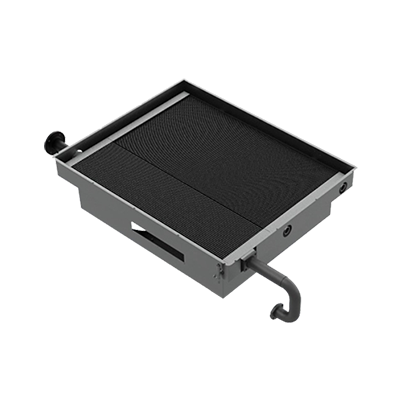

⑤ Classic cooler design

● Combined oil and after cooler

● Anti corrosion surface coatings

● 20% oversized

● After cooler (optional)

⑥ Innovative vectorial inverter

● CE/UL Certification

● Meet EMC C3 and C2

● Wide voltage design

● Built-in DC reactor

● Independent cooling air duct design

⑦ Plot® Touch controller

● 7.0 inch full color touch screen LCD

●Protection against overloading, overpressure, overheating, phase unbalance plus 13 more protections.

● Modbus RTU.

⑧ Inlet valve

● Optimizes the inlet flow

● No blow-off losses

● Maintenance free pipe design

●Large suction area, low pressure application

⑨ Oil filter

● High efficiency oil filter

● Oil particles down to 0.1 micron

● Smooth and well-lubricated oil system

● Multiple oil filter combination, stable operation

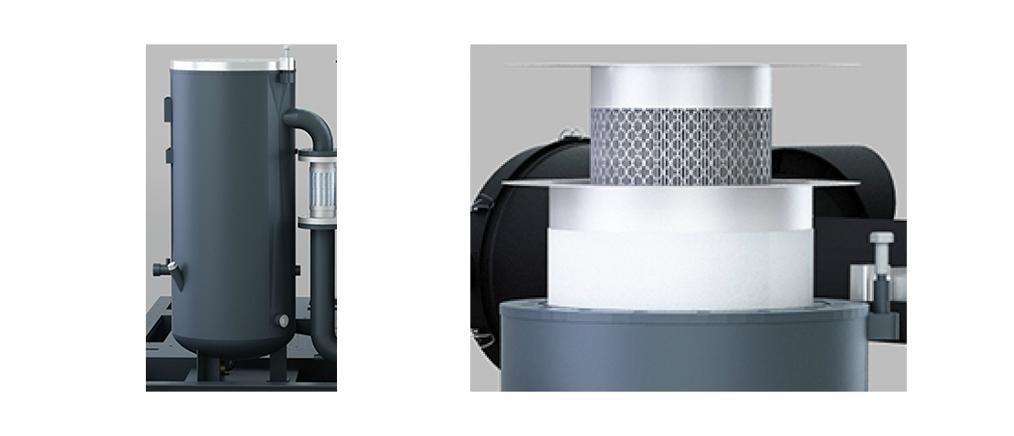

⑩ Oil gas tank & Built-in separation system

●Oversized air and oil tank, improved air/oil separation process

●The high efficiency oil separator ensures that the oil

carry over is less than 3 ppm.

● System pressure loss < 0.02 MPa

⑪ Electrical control cabinet

● Siemens core electrical components.

⑫ All-steel internal pipe system

● All steel internal pipe work, no leakage, longer life

● Less pipe pressure loss

PRODUCT PARAMETER

Note:

Data conforms to ISO 1217 (Pressure 1 bar (a), Temperature 20 deg C, R.H 0%)

Standard voltage is 380V/50HZ/3P, other voltage is available.

The recommended best capacity range is 60%-100%.

Alpine/high altitude, high temperature, high humidity, high dust loads or other adverse working conditions will require specialized custom designs. These are available on special request.

We reserve the right to make changes and improvements to the design and appearance.

Specifications may change without prior notice.